Overview

Nireco is involved in your production processes, offering systems that will enhance your product quality!

-

Sister machine to the BCON5000

By offering only single-sided inspections and functions, we have achieved a more affordable price.

-

The BCON series ̶ expanding through Nireco’s proven performance

The BCON3500 uses the inspection technologies that Nireco has developed, to help improve product quality through reliable inspections. It inspects a wide variety of substrates, “visualizes” the inspection, and is easy to operate.

BCON3500’s new features

Examples of detected defects

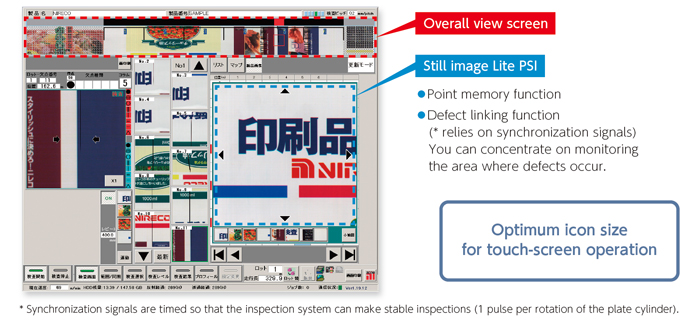

Screen layout

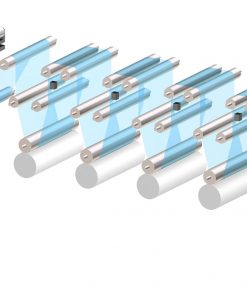

Nireco LED lighting ̶ the product of technology and know how

High-brightness LED lighting uses basic optical principles to enable the inspection of a wide range of substrates.

Feature

- Illuminates the web with the optimal level of brightness

- A standard light-emitting length of 1400 mm. (When width = 1200 mm)

- Can be manufactured in 200-mm-unit lengths. (Optional)

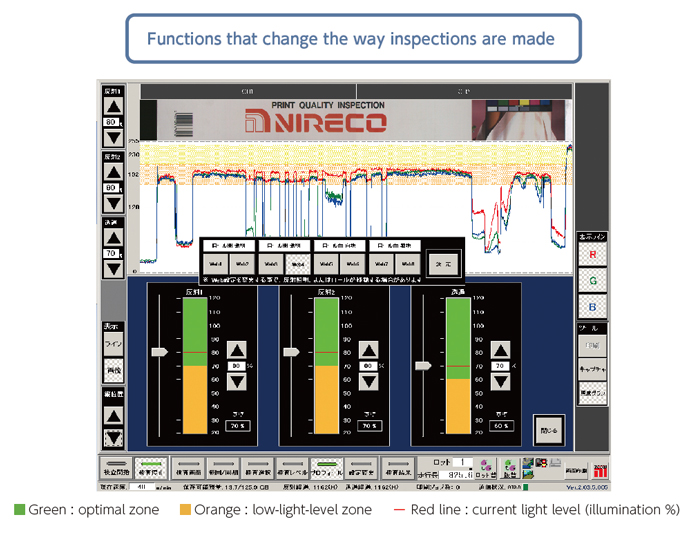

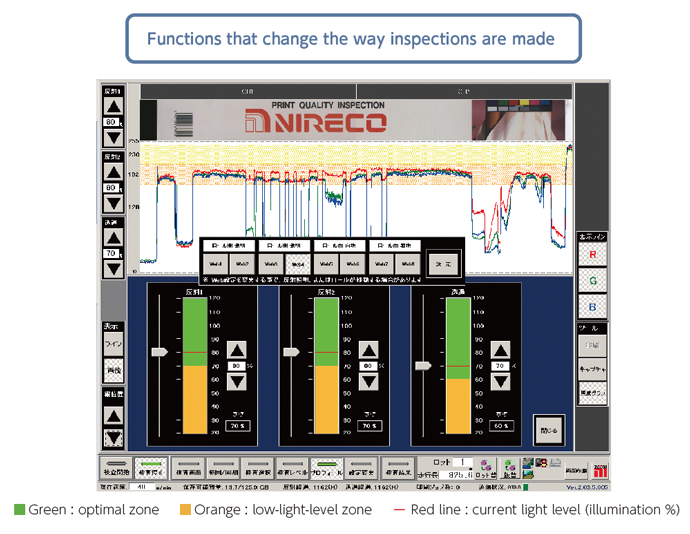

Profile screen

LED illumination gauge

This feature detects printing and web processing defects and graphically displays the appropriate amount of illumination from lighting systems required for a wide variety of different substrates, providing support to the factory floor through its intuitive operating environment.

LED profile ON and SAVE functions

A feature inherited from the BCON2000: you can check the camera signal waveform during the inspection. You can also save the camera signal waveform data that you have checked.

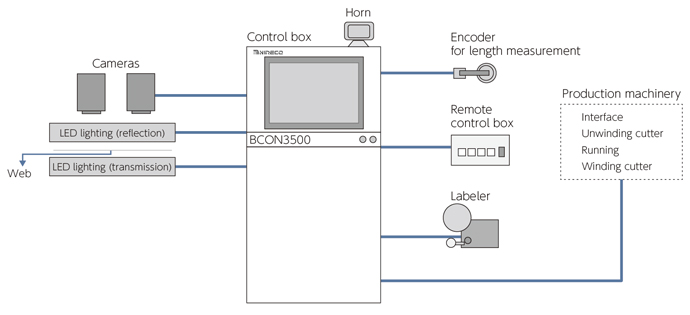

Equipment configuration

Specifications

| High-speed 4096-pixel 70 MHz cameras | |

|---|---|

| High-brightness LED lighting | |

| A total of 8 defect-detection circuits |

|

| An all-in-one processor |

|

| Signal cable length |

|

| Viewer PC connection (optional) | |