Overview

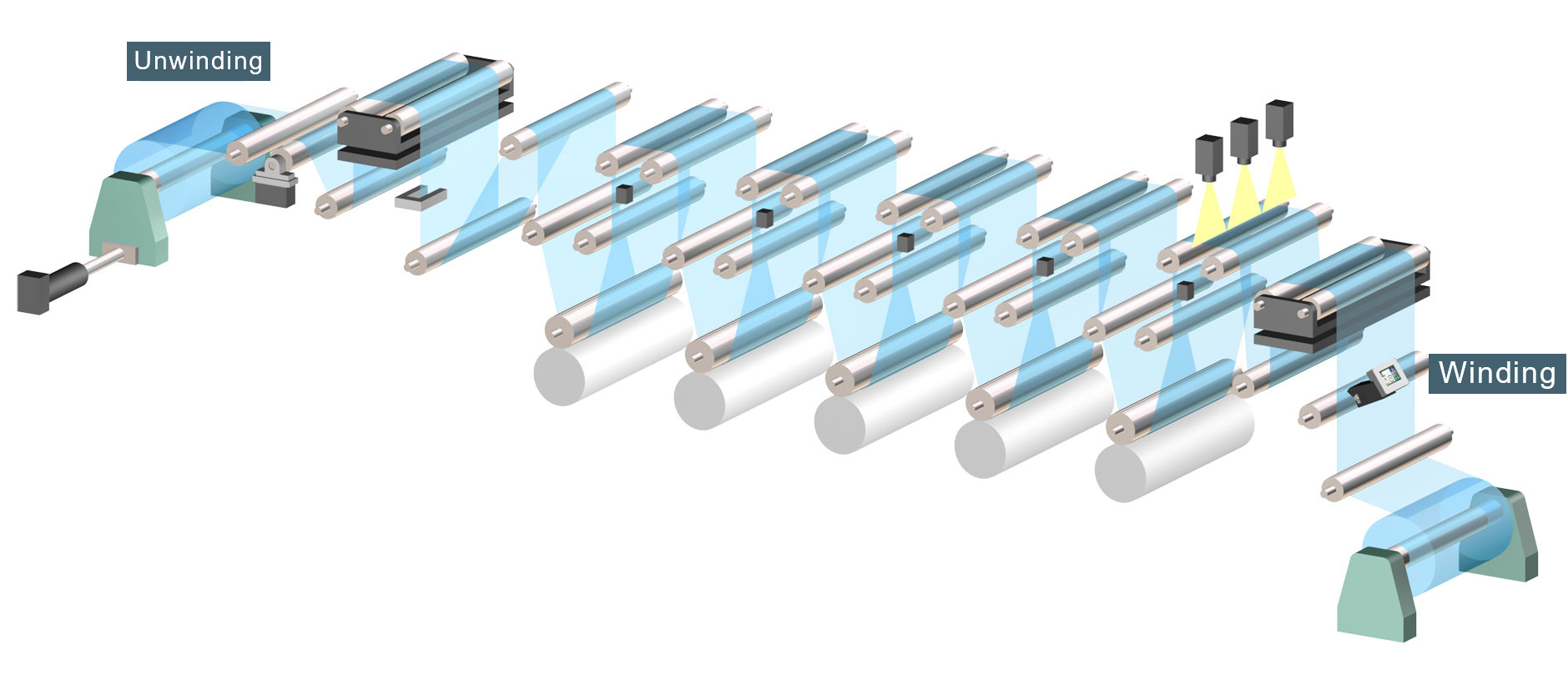

Introducing a bearing-type tension sensor that can be cleaned with water.

The CJ sensor is essential for tension control of sophisticated plastic films used in leading-edge industries, including flat-screen TVs, rechargeable batteries, thin and light solar cells, and organic EL lighting which is expected to become the next generation of lighting. The CJ series of tension sensors are bearing-type sensors, so they can easily be installed on existing lines.

Feature

- The CJ tension sensor has excellent dynamics, and its high spring-steel rigidity provides a high resonance point, making it ideal for high-speed lines.

- The load displacement of the MJ tension sensor is extremely low, making it effective for thin web lines (i.e., film, foil, etc.).

- The stainless version has an IP66-compliant protective housing that can handle being splashed with water when cleaning a production line.

- The use of a mono-block structure provides outstanding linearity and hysterisis.

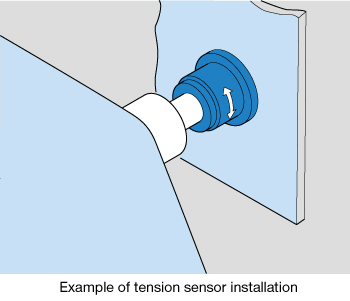

- Because the bearing unit and sensor are integrated, the sensor has a low profile and requires minimal installation space, enabling it to easily be installed even in confined spaces.

Specifications

| Model | CJ200 | CJ500 | CJ1000 |

|---|---|---|---|

| Diagram number | MD0000360 | MD0000370 | MD0000380 |

| Diagram number with adapter unit | MD0000450 | MD0000460 | MD0000470 |

| Rated tension (N)*1 | 200 | 500 | 1000 |

| Maximum roll load (N)*1 | 200 | 500 | 1000 |

| Maximum overload*1,5 | 2000 | 5000 | 10000 |

| Roll displacement (μm·N) | 0.12 | 0.06 | 0.035 |

| Resonance frequency (Hz) *2 | 143.8 | 128.6 | 119.1 |

| Frequency response (Hz)*3 | 300 | ||

| Main unit mass (kg) | 1.0 (1.6) | ||

| Direction of resultant tension force | Forward or reverse | ||

| Mounting angle | Any desired angle | ||

| Supply voltage | ±15VDC ±1V (+15V/50mA,-15V/10mA) | ||

| Ambient temperature/humidity | 0 to +50°C, 35 to 85%RH (No condensation permitted) | ||

| IP Protection Rating | IP30 | ||

Notes:

*1. The figures for rated tension, maximum roll load, and maximum overload are for double-sided detection.

*2. The resonance frequency figures are for the tension load during double-sided detection and at maximum roll load.

*3. The frequency response figure is with respect to a change of 1/10 in the rated tension.

*4. The figure in parenthesis is the mass including the adapter unit.

*5. The maximum overload represents the maximum value of the force exerted in the direction of the resultant force.